Ensuring Top-Quality of Our A-frame Campers

The allure of camping and exploring the great outdoors has been a timeless pursuit for adventurous souls. For many, campers offer the perfect solution to combine the comforts of home with the freedom of nature. However, ensuring the quality of manufacturing campers is crucial to meet customer expectations and guarantee long-lasting satisfaction.

At Aliner, we take quality control seriously, always looking to improve our practices, educate our team, and stay in touch with consumer interests and feedback. Our team goes above and beyond to create consistent, quality campers that keep our Aliner army growing and coming back for more.

Investing in Research and Development

The foundation of any quality A-frame camper lies in its design and engineering. By taking the time to invest in resources, we are able to develop well-thought-out camper designs that prioritize functionality, durability, and user experience. Engaging with designers with a passion for camping can lead to innovative features and efficient use of space, which is the focus of our research and development team.

Selecting Quality Materials

Using high-quality materials is a non-negotiable aspect of Aliner’s manufacturing process. From the exterior shell to the interior fittings, every component must be made of durable and weather-resistant materials to withstand the rigors of various terrains and climates. During our weekly product development meetings, supervisors and managers meet to discuss the progress of testing and implementing these new materials. We work closely with many local vendors to ensure the highest quality in our supply. Well-chosen materials enhance insulation, reducing energy consumption and improving comfort for our customers.

Upgrading Construction Techniques and Equipment

A sturdy and robust construction is essential to ensure the longevity of Aliner campers. We have adopted reliable, precise construction techniques, including modern welding methods, fasteners, and adhesives that promote structural integrity. Comprehensive quality control during the manufacturing process can catch any defects before they become issues for the end-users.

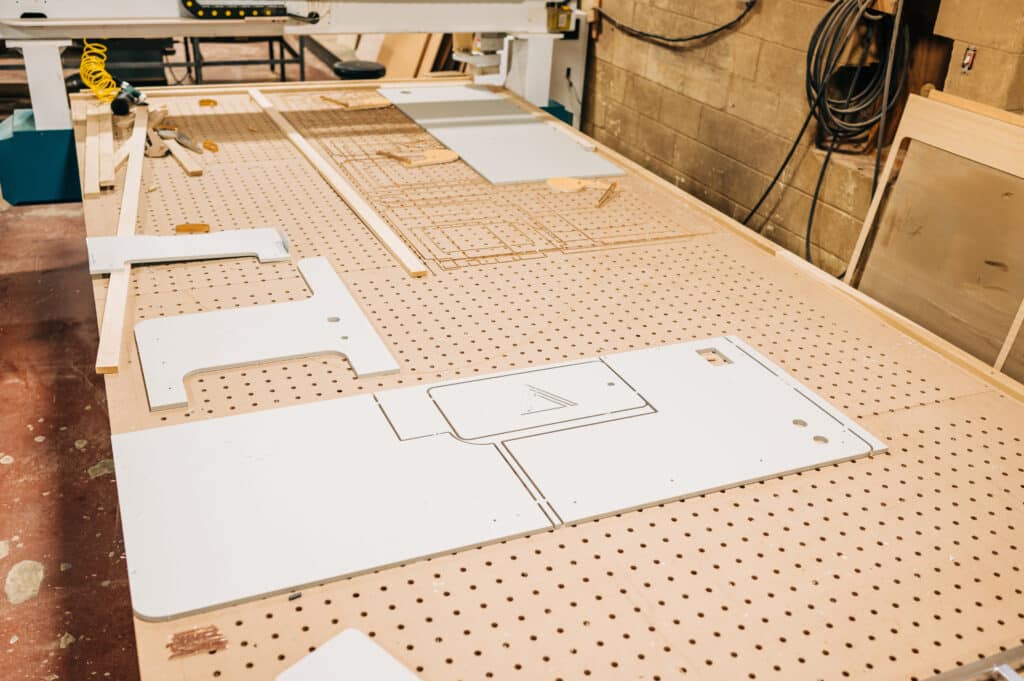

Quality control also depends on the precision of your materials, especially in a foldable camper like ours. Upgrading to CNC machining equipment has given us the ability to ensure precision on our materials, which helps them fit together perfectly.

CNC machines have many benefits, including:

- Zero defects

- Greater accuracy

- Quicker assembly

- Lower production costs

- Reduced energy consumption

- Optimization of material usage

When we make upgrades to our equipment and practices, we also improve the quality and consistency of our A-frame campers. Providing our customers with a high-quality camper is always the ultimate goal of our manufacturing process. In fact, we have maintained a low warranty rate with our campers over the years.

Testing and Evaluating the Final Product

Quality assurance should be an integral part of the manufacturing process. Rigorous testing at various stages ensures that each component meets the required standards before integration into the final product. Camper manufacturers should conduct safety tests, water resistance tests, and functionality checks to validate the overall quality of their products.

Implementing Customer Feedback

Customer feedback is invaluable for camper manufacturers. Listening to the needs and concerns of campers who have used their products can lead to improvements and optimizations. As a team, we are always listening to what our customers are saying on social media, at rallies, and during calls or tours at the plant. Their experiences with the campers provide us with feedback on the functionality, improvements, and issues that may arise in the great outdoors. By seeking feedback, we can then take this information and improve our product to meet consumer demand and interests over time.Â

Embracing Sustainable Practices

As the RV moves forward into the 2020’s, there is a focus on eco-friendly practices, materials, and solutions. By incorporating sustainable manufacturing practices, we can not only help the environment but also align with the values of modern consumers. Using eco-friendly materials, like solar panels, optimizing energy consumption during production with equipment, like our electric forklift, and adopting recycling practices, like the Viacom plastics recycling program, contribute to the overall quality perception of the camper brand.

Providing Ongoing Team Member Training

Behind every quality A-frame camper is our skilled and dedicated workforce. At Aliner, we invest in continual training and development of our employees to ensure that they possess the necessary expertise and knowledge to deliver top-notch products. Not only does this promote safety in the workplace, but it ensures consistency in our practices and quality in our campers.

The quality of our campers is a reflection of our commitment to excellence and customer satisfaction. With high-quality campers, we can continue to ensure customer loyalty – and more importantly, inspire a deeper appreciation for the exploration of the great outdoors.